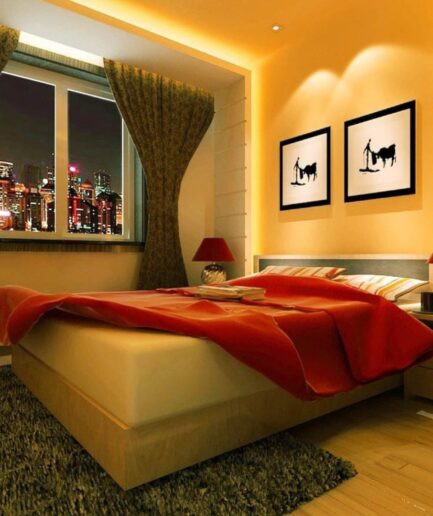

LED Strips

A LED strip light (also known as a LED tape or lace light) is an adaptable circuit board populated by surface mounted light-emanating diodes (SMD LEDs) and different parts that usually accompanies an adhesive backing. Traditionally, strip lights had been utilized exclusively in accent lighting, backlighting, task lighting, and decorative lighting applications. Increased glowing efficacy and higher-power SMDs have allowed LED strip lights to be utilized in applications, for example, high brilliance task lighting, fluorescent and halogen lighting fixture replacements, circuitous lighting applications, ultraviolet (UV) assessment during manufacturing cycles, set and outfit design, and in any event, developing plants. Variables in strip lighting consist of water resistance, variety, adhesives, decision of SMD, driving voltage, control type, and whether it is constant momentum or constant voltage layout. Uncoated LED tape is not considered to have any resistance to water entrance, yet may be rated as IP20 for some physical entrance resistance. Such tapes are generally low voltage and safe for skin to contact yet can be shorted by fine metal items. Water resistant strip lighting is shrouded in a heat leading epoxy or silicone to shield the hardware from direct contact with water, and can be rated IP65, IP67, or with suitable sealed associations IP68. Both coated and uncoated LED tapes have a two sided adhesive backing to adhere to walls, work areas, doors, and so forth.

12V Constant Voltage Drivers

A 12V DC LED system is a typical voltage platform. Many electrical systems operate on 12V DC, and you are probably already familiar with several of these. Many batteries for vehicles including boats and RVs operate on 12V DC, which makes utilizing a 12V LED system an easy decision for these applications, as there is no requirement for any additional transformers or power supplies to change over the voltage – your LED lights can be connected straightforwardly. Then again, regardless of whether you won’t utilize batteries, you will in any case have to depend on power supply units. 12V is an exceptionally normal voltage level primarily because of its generally expected use in desktop processing. This makes power supplies readily and cheaply available and can assist with diminishing your purchase costs. 12V LED systems have a lower electric shock risk. When it comes to LED item safety, optical, shock and fire risk are often considered. Because 12V is a much lower voltage compared to line voltage (120/240V), it is more challenging for the electrical flow to conquer the implicit resistance of human skin and different articles. This makes it safer for hobbyists who want to explore different avenues regarding items like LED strips. Generally, in the event that you accidentally create a short out, you won’t see any sparks or uproarious bangs that you would see with line voltage systems.